Equipment Overview

A heat press is a machine engineered to transfer a design or graphic onto a substrate, such as a t-shirt, mug, tile, metal etc. It does this with the application of heat and pressure for a set period of time. While heat presses are often used to apply designs to fabrics, they can also be used to print designs onto mugs, plates, jigsaw puzzles, metals, some plastic, leathers, wood and other products.

Most heat presses currently on the market use an aluminium upper-heating element with a heat rod cast into the aluminium or a heating wire attached to the element. Machines manufactured in Europe and the USA generally use an element which is attached to the aluminium block, so that should the element burn out, it’s very quick and easy to replace.

Heat presses are available with a variety of differently shaped elements, a flat element for T-shirts and other flat materials, curved for caps, round for mugs, circular for plates and special shapes for example for pens. The image or graphic to be transferred is printed on a special transfer paper which allows the image to transfer with the application of heat and pressure.

As agents for Geoknight in the USA, and MUGGIT out of the East, we distribute a wide variety of heat presses from home to industrial units.

We also have spares on hand and competent technicians who can repair our presses.

Printers Overview

A sublimation printer is a printer with sublimation inks loaded. There are very few printer brands on which sublimation inks work. This is due to the way the print heads and ink delivery mechanisms operate across the different brands.

There is however a massive difference between a printer built specifically for sublimation inks and a printer modified for use with sublimation inks. A printer modified for use with sublimation ink loses its guarantee as a soon as 3rd party ink is added to it. Also, a printer modified for use with sublimation ink does not have the hardened ink feeding mechanisms or print heads required for long term reliability.

An important issue with sublimation printing is that colour profiles must be supplied by the ink manufacturer for the inks that you are using. Many companies selling you sublimation ink will claim that no profiles are required - This is a clue that you are dealing with a company that has no clue what they are selling.

Sawgrass was the first printer manufacturer who specifically manufactured small format desktop sublimation printers.

Sawgrass printers come with advanced colour matching software specific to the inks, printer, media and substrates used for sublimation.

Full technical support, servicing and repair is supplied by JG Electronics locally.

DTF - Direct to Film Printing technology

This is an advancing technology that has some of the lowest print costs in the industry yet coupled with the best washability. The cost to print onto a dark material is slightly more than a white substrate with no more hassle or different papers to use and the image quality and wash durability are the same.

The printer used is a modified inkjet printer on the low-end system and purpose-built printers on the higher end. The image is printed with special inks onto a film. Once printed a powder is sprinkled onto the still wet print and put under infrared heat to dry. For production work, there are now automatic powder application & heat curing machines from which the print rolls from the printer into this machine and out onto the print take-up roller, thus allowing for an almost completely automated process before the actual transfer onto the substrate.

Vinyl Cutters Overview

Silhouette® vinyl cutters is a computer-controlled machine that comes with Silhouette Studio® software. Just like a printer controls a nozzle, the software on the computer controls the movement of a sharp blade over the surface of the material that is being cut. This blade is used to cut out shapes and letters from various types of material e.g., heat transfer vinyl (HTV), sticker vinyl, paper, cardstock, material, felt, leather, etc.

The Silhouette® range of vinyl cutters are quick and easy to set up and the software is user friendly even if you are a beginner. It also does not require a lot of capital to start up your very own business. Also great for crafters and hobbyists to simplify various cutting tasks.

If your business revolves around making custom t-shirts with a heat press machine, then you will definitely need a vinyl cutter by your side. A great vinyl cutter will help you accurately and quickly cut your heat transfer vinyl into your desired artwork or designs that look professional on your client's t-shirts.

When purchasing a vinyl cutter from us, your one-on-one training is included.

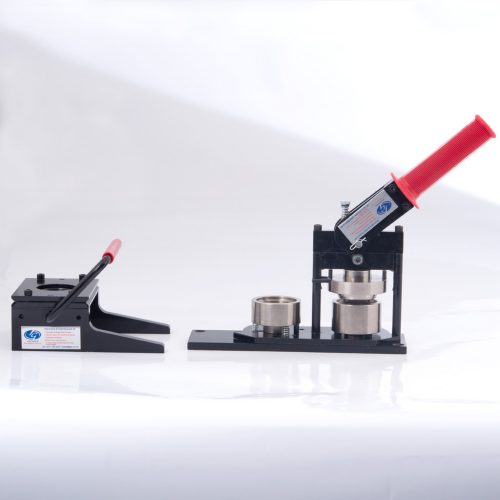

A Button Badge press is the perfect add-on to any printing business, and should seriously be considered. This in-expensive, yet extremely robust and durable machine, allows you to make the ever-popular button badges, and thus make more money.

Button badges are a cost-effective advertising medium and are very popular for corporate giveaways, fundraising and political events.

School kids (especially girls) collect them, which is another great market.

Our machines are sourced from the USA and are extremely tough, to give you years of great service. These

Our machines are available in 25mm, 37mm and 56mm varieties. As these machines are industrial grade, each size is a different machine.